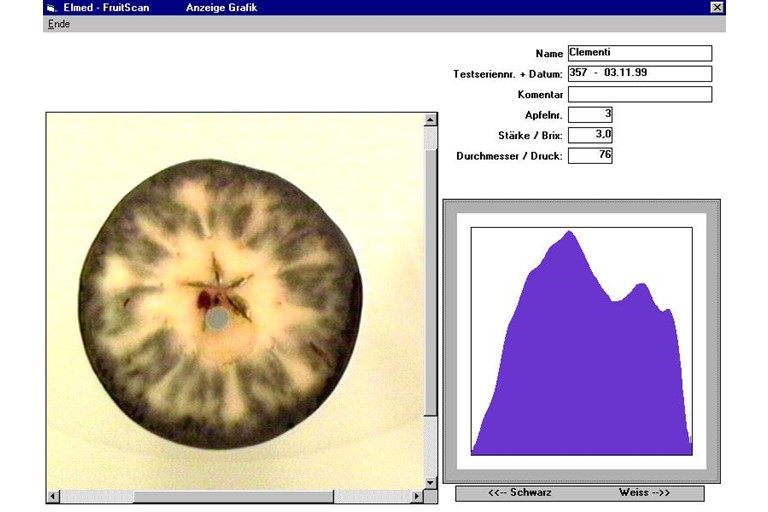

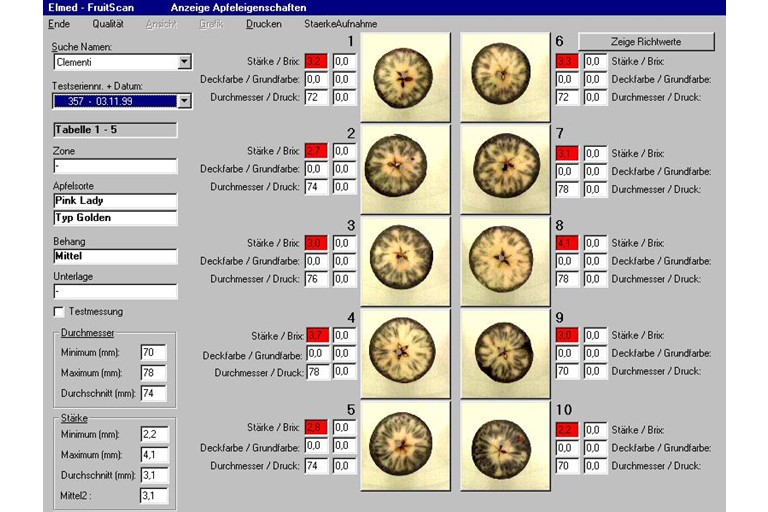

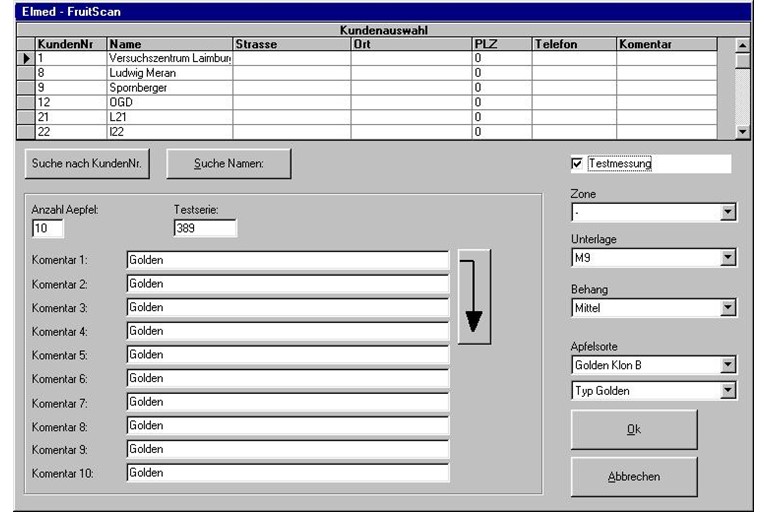

For the correct measurement of the starch container in apples and/or pears by Fruitscan a great expert is not necessary. The intensity tables are graphically visualised and Fruitscan is a supplementary equipment of great support for fruit/vegetables sector and for the research centres that take the greatest advantages from the fruit storage.

Modern technology for starch measurement!

What is Fruitscan?

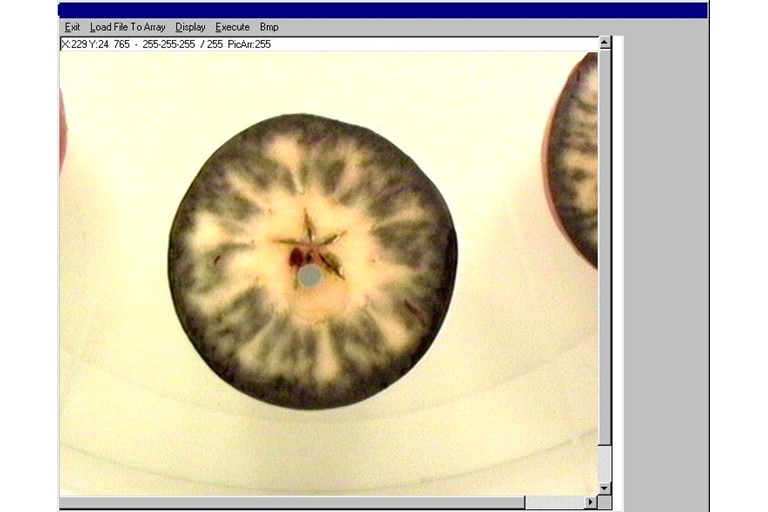

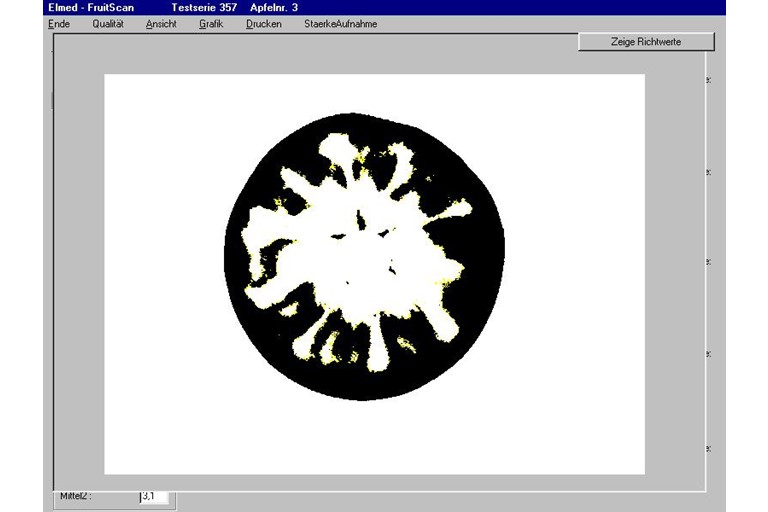

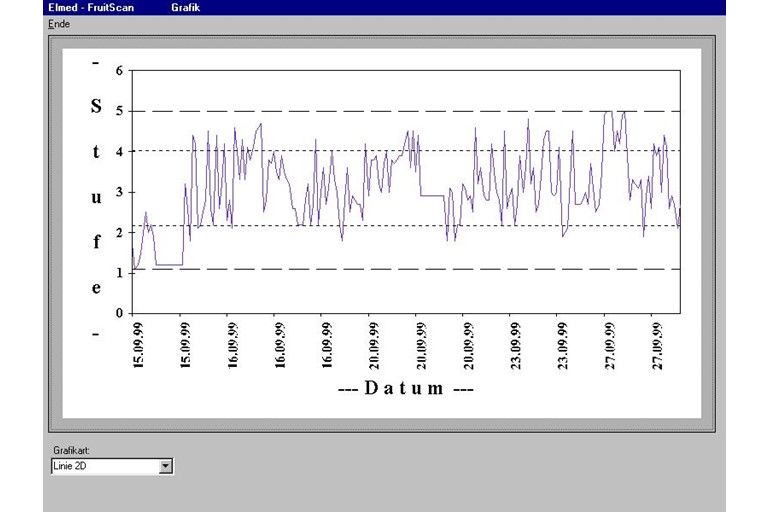

Fruitscan is a new conception instrument allowing to determine in a quick and reliable way the starch content in fruits (apples or pears) under specific analysis. Thanks to Fruitscan, ripeness tests produce repeatable results and comparable. The instrument working does not need specific knowledge; The Fruitscan software makes the fruit acquirement easy and after a short analysis visualises the results without derived errors or wrong readings. The precise knowledge of this value, indicating the fruit ripeness, is of great use to determine the perfect period for the harvest.